Certified Reference Material for XRF Analysis

Catalog No :

CAS Number :

Brand :

In Stock

Specifications:

| Application | Elemental Analysis | ||

| Storage Temperature | Ambient | ||

| Product Type | Calibration Standard | Forms | Solid |

| Product Grade | Analytical grade | ||

Certified Reference Materials (CRMs) are essential for XRF (X-ray Fluorescence) analysis, providing benchmark standards to ensure accurate and reliable results in material characterization. These materials are widely used in industries such as metallurgy, manufacturing, and quality control to validate analytical procedures and instrument calibration. The following details pertain to CRMs for Copper-based alloys, specifically designed for their respective compositions.

Product Details by Alloy

| Product Code | Alloy Name | Composition Highlights | Applications |

|---|---|---|---|

| C836 | Copper 836 | Lead-free red brass alloy. Contains copper, tin, and zinc. | Used in industrial and architectural castings. |

| C844 | Copper 844 (Pb Red Brass) | Contains copper, lead, tin, and zinc. | Plumbing, pump components, and valves. |

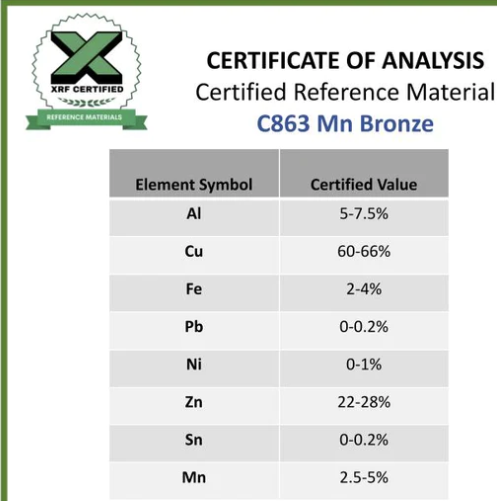

| C863 | Copper 863 (Mn Bronze) | Manganese bronze alloy with copper, zinc, manganese, and iron. | High-strength applications like marine hardware. |

| C875 | Copper 875 (Si Bronze) | Silicon bronze with copper and silicon as primary components. | Electrical connectors, bushings, and springs. |

| C903 | Copper 903 (Sn Bronze) | Tin bronze alloy with copper and tin. | Bearings, gears, and wear-resistant parts. |

| C922 | Copper 922 (Sn Bronze) | Tin bronze with copper, tin, and a small percentage of lead. | Ship propellers and fittings. |

| C932 | Copper 932 (Pb Cu) | Leaded copper alloy with significant lead content for machinability. | Bearings and bushings with high wear resistance. |

| C937 | Copper 937 (Hi Pb Sn Bronze) | High-lead tin bronze alloy. | Applications requiring high lubricity and load capacity. |

Key Features

- Traceability:

- Each material is certified to internationally recognized standards, ensuring precise composition data.

- Supports calibration for XRF instruments with exact elemental values.

- High Purity and Consistency:

- Homogenized and stable material compositions ensure consistent results across different batches.

- Validated through rigorous testing methods.

- Wide Applicability:

- Covers a broad spectrum of copper-based alloys for various industrial uses.

- Suitable for identifying and quantifying elements such as Cu, Sn, Zn, Pb, Fe, Mn, and Si.

- Reliable Performance:

- Helps achieve reproducible and accurate results for elemental analysis in production, R&D, and quality assurance.

Applications

- XRF Instrument Calibration:

- Serves as a standard for calibrating XRF instruments for the analysis of copper-based alloys.

- Quality Control:

- Ensures that the composition of materials meets specification requirements in manufacturing.

- Research and Development:

- Supports the development of new materials by providing accurate baseline data.

- Material Verification:

- Confirms material grades and composition in procurement and supply chains.

- Failure Analysis:

- Identifies alloy composition in post-failure investigations.

Specifications

- Format: Solid CRM (typically in the form of discs or blocks).

- Material Type: Homogeneous metal alloy.

- Certification:

- Each material comes with a detailed certificate of analysis (CoA).

- Includes elemental composition with defined uncertainty values.

- Storage: Store in a dry, clean environment to prevent contamination or corrosion.

Advantages

- Accuracy: Ensures precise element quantification for copper and its alloys.

- Efficiency: Minimizes errors in analytical measurements.

- Versatility: Covers a range of copper-based alloys for diverse industrial applications.

- Durability: Designed for long-term use without degradation in standards.

The Certified Reference Material for XRF Analysis: Copper Alloys provides a comprehensive solution for ensuring accurate and reliable material characterization in copper-based alloys. By covering key alloy types, these CRMs enable robust calibration, quality control, and material verification processes across multiple industries.

- Alloy: Copper 863 (Mn Bronze) Copper 875 (Si Bronze) Copper 836 Copper 903 (Sn Bronze) Copper 932 (Pb Cu) Copper 922 (Sn Bronze) Copper 937 (Hi Pb Sn Bronze) Copper 844 (Pb Red Brass)

0

0