Thermo Scientific™ Triphenyl phosphate 99+%

Catalog No :

CAS Number :

Brand :

In Stock

Specifications:

| Storage Temperature | Ambient | ||

| Product Type | Laboratory Chemical | Forms | Powder |

| Product Brand | Thermo Fisher Scientific™ | ||

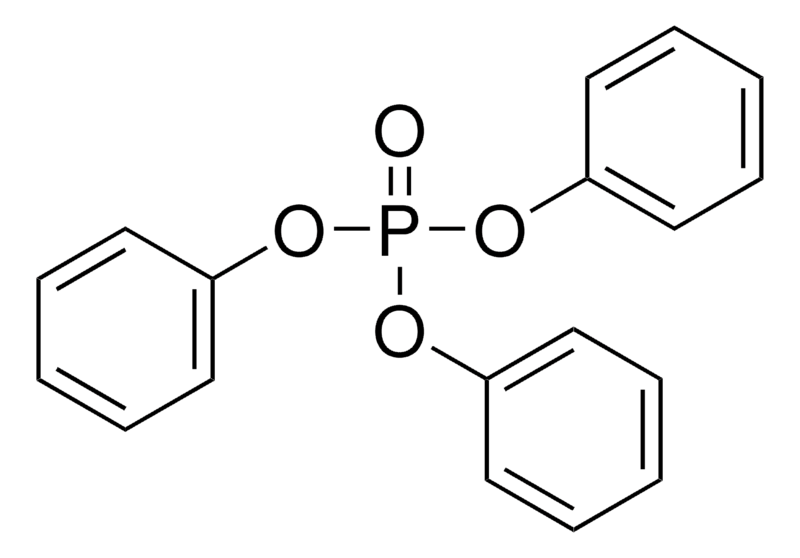

| Product Grade | Analytical grade | Formula | C₁₈H₁₅O₄P |

Specifications:

| Feature | Test Results |

|---|---|

| Appearance | White flakes and/or pastilles |

| Infrared Spectrum | Conforms |

| Melting Point | 47–53°C |

| Water Content | ≤0.1% |

| Free Phenols | 0.005% |

| GC Purity | ≥99.0% |

| Color Scale | ≤50 APHA (after heat treatment) |

| Acid Value | ≤0.05 mg KOH/g |

Description:

Triphenyl Phosphate (TPP) is a high-purity chemical primarily used as a plasticizer and flame retardant in various industrial applications, including the manufacturing of polymeric materials, synthetic resins, and plastic compounds. Due to its excellent chemical stability and ability to impart flame resistance, it is widely used in polymeric materials, coatings, and adhesives.

TPP is also utilized in the production of solvents, oil additives, and as a stabilizing agent in some chemical processes. Its properties make it essential in applications that require thermal stability, chemical resistance, and fire safety.

Key Features:

- High Purity: The product has a GC purity of 99.0% and a low water content (≤0.1%), ensuring high quality for use in precise formulations and processes.

- Stable Melting Point: The melting point range of 47–53°C makes it a stable compound for various applications requiring controlled temperature conditions.

- Free of Contaminants: The low acid value (≤0.05 mg KOH/g) and minimal free phenols (0.005%) ensure the product is free of contaminants that could interfere with sensitive applications or reactions.

- Environmental Considerations: Rated as GHS09, Triphenyl Phosphate is classified as an environmental hazard and should be handled with care according to environmental safety protocols.

Applications:

- Flame Retardants: Widely used as a flame retardant in plastics, textiles, and synthetic resins, Triphenyl Phosphate helps improve fire resistance in materials.

- Plasticizers: Commonly employed as a plasticizer to increase flexibility and durability in polymers and synthetic resins.

- Solvents and Additives: Used as a solvent and stabilizing agent in various chemical processes, including oil formulations and cosmetics.

- Polymer Manufacturing: TPP is an important component in the production of polymers and coatings that require enhanced chemical stability and thermal resistance.

- Chemical Synthesis: Used in the synthesis of chemicals where its role as a stabilizer or additive ensures the desired properties of the final product.

Storage:

- Store at ambient temperature in a cool, dry place. Ensure the container is tightly sealed to prevent contamination and exposure to moisture.

Safety and Handling:

- Environmental Hazard: As TPP is classified as a GHS09 environmental hazard, it should be handled following appropriate safety protocols. Avoid release into the environment.

- Personal Protection: Wear appropriate protective gloves, goggles, and lab coats when handling the chemical to prevent direct contact and ensure safe handling.

- Follow all local regulations for disposal and storage.

Triphenyl Phosphate 99+% is a high-quality chemical essential for plasticization, flame retardancy, and chemical stabilization. With its high purity and exceptional properties, it is widely used in industrial applications, chemical synthesis, and manufacturing processes requiring flame-resistant and chemically stable materials.

0

0